Composite materials ar e used where it is applied equall y on vessel. Ad COPV Filament Winding Pressure Testing Autofrettaging.

Pdf Burst Strength Analysis Of Composite Pressure Vessel Using Finite Element Method Semantic Scholar

Composite Pressure vessels design.

. 7222 Characteristics of the Components in Composite Pressure Vessels. Design according to T-Sai Wu failure criteria as given below. Those shown in the figure above are the twelve sections of the code.

Main benefits are it is less heavy but having a high cost as compared to other two. In these Vessels Metal liner. Prediction of the ultimate strength of a designed vessel is done using various failure theories.

Moreover the stacking sequence is very crucial to the strength of. The focus of this research is to evaluate the reliability of pressure vessels made of composite materials carbon and glass fiber with respect to stress and burst. To properly design a pressure vessel it is necessary to.

Industrially produced composite pressure vessels are made by filament winding tows of high strength carbon fiber. The focus of this research is to evaluate the reliability of pressure vessels made of composite materials carbon and glass fiber with respect to stress and burst pressure. Boiler and Pressure Vessel is divided into the following sections.

Heat Exchangers Columns Piping Pressure Vessels Reactors Metal Finishing And More. Cylindrical composite pressure vessels incorporating additional constraints like pattern consistency and strain compatibility at the cylinder dome intersection. The use of composite materials improves the performance of the vessel and offers a significant amount of material savings.

3 Where 3 is. And if the criteria used is the inverse of strength index. This project is proposed to analyse and design a cylindrical pressure vessel made up of composite material.

Ad Filters Heavily Used In Aerospace Support Flight Applications. Standard Custom Designs including Quick-Open ASME available Engineer Support. The primary goal of this design project is to use the knowledge gained about composites and their advantages to create a carbon fiber epoxy pressure vessel.

I need to repair cracks in of our pressure vessel and. Dear experts ASME PCC-2 is a post construction code for vessel repairs and alterations using composite materials. The most notable pressure vessel construction standard is Section X of the ASME Boiler and Pressure Vessel Code.

Usually composite pressure vessels are designed for minimum mass under strength constraints. For applications in very corrosive services composite tanks and vessels. A number of factors must be.

The new composite material considered is waspaloy. The composite materials chosen for modeling and analysis of pressure vessel are carbon fiber reinforcement polymer CFRP and HM carbon epoxy. Ad Trusted By Industries Around The Globe For Corrosion-Resistant Process Equipment.

Composite pressure vessels tend to fail in their composite pressure vessels parts. The results reveal that. Ad Designs Manufactures A Broad Range Of Pressure Vessels Reactors.

The design of these parts is the most important issue for such vessels 32. A graphical analysis is presented to find optimum fiber orientation for given layer thicknesses. Ad COPV Filament Winding Pressure Testing Autofrettaging.

The design of a pressure vessel is entirely reliant upon mechanics of materials.

Type Iv Composite Overwrapped Hydrogen Pressure Vessel Source Process Download Scientific Diagram

Advanced Aerospace Structures Lecture 4b Composite Pressure Vessel Netting Theory Youtube

Virtual Testing Of Composite Pressure Vessels Asme

A New Concept For A Modular Composite Pressure Vessel Design Sciencedirect

Composite Pressure Vessel Resources

Composite Pressure Vessel Design And Simulation

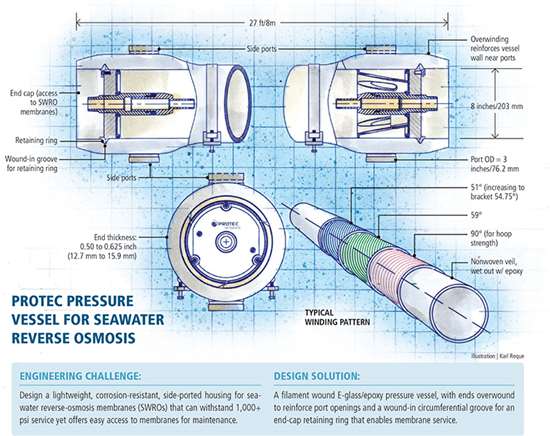

Designing Pressure Vessels For Seawater Desalination Plants Compositesworld

Monitoring Of Type Iv Composite Pressure Vessels With Multilayer Fully Integrated Optical Fiber Based Distributed Strain Sensing Sciencedirect

0 comments

Post a Comment